We love to hear from you !

Product details Parameters

TM934-1 Barcol Impressor

Features:

1.A portable indentation hardness tester.

2.Single hand operation; no operating experience required; can test any workpiece

which is reachable in any site.

3.Wide valid testing range equivalent to Brinell hardness 25-150HBW. Used to test

the hardness of all kinds of aluminum, from very soft aluminum to very hard

aluminum alloys.

4.Extended application. Model 934-1 is applied to test the hardness of aluminum,

aluminum alloys, copper, copper alloys, fiber reinforced plastics and rigid plastics etc.

The improved model of it is available to test very soft metals such as lead and tin and

other soft materials such as soft plastics, rubber, felt and leather etc.

5.High sensitivity. Featured with 100 scales, much more sensitive than Webster

hardness testers applied in aluminum alloys industry.

6.No supporting required. Can test from only one side of the workpiece. No need to

move or support the workpiece. Used to test super large and thick worpieces and

assembly parts.

7.Comply to standard ASTM B648-2000.

8.Easy conversion. The test results can be converted to HB, HR, HV and HW easily

through conversion table.

Application:

1.Barcol Impressor is mainly applied to test aluminum and aluminum alloys.

Webster is used to test aluminum alloy extrusions, sheet and tubings.

Barcol Impressor is suitable to test pure aluminum, soft aluminum alloys,

super thick aluminum alloys, aluminum alloys bars and assembled aluminum

alloys parts (e.g. al-alloy door &window, scaling ladder etc.)

2.Relevant Standard: ASTM B648 (Test Method for Indentation Hardness

of Aluminum Alloys by Means of a Barcol Impressor)

3.Barcol Impressor is also used to test fiber reinforced plastics and rigid plastics etc.

Relevant Standard: ASTM D2583-07(Test Method for Indentation Hardness of Rigid

Plastics by Means of a Barcol Impressor)

4.The improved models of Barcol Impressor are available to test softer plastics, very

soft metals, rubber and leather etc.

Disadvantage:

1.The surfaces of work pieces need to be broad and flat. It is inconvenient to

test the hardness of strips, small-sized pieces or work pieces with curved surfaces.

2.There will be conversion error. When testing the hardness of aluminum section

materials, the Barcol hardness need to be changed into Webster hardness, but there

is 2.7 HW discrepancy between Barcol conversion table and GB Standard YS/T420-

2000, so the Barcol conversion table should be used cautiously.

Standard package

1.Tester

2.Spare indenters (2 pcs)

3.High value Standard hardness block (1 pc)

4.Low value Standard hardness block (1 pc)

5.Calibration wrench

6.Supporting foot

7.Carrying case

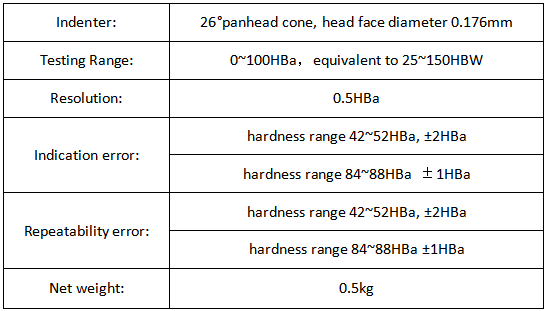

Technical Parameters:

Pay attention to TMTeck

Add:#613A, LinJI Industrial Building ,No.53 of Shun Ren Road ,Lin He Industrial park, ShunYi District ,101300 Beijing ,China

Tel:86-010-8944 5181/86-010-8944 4420

Fax: 86-010-8944 4420

Email: info@tmteck-ndt.com